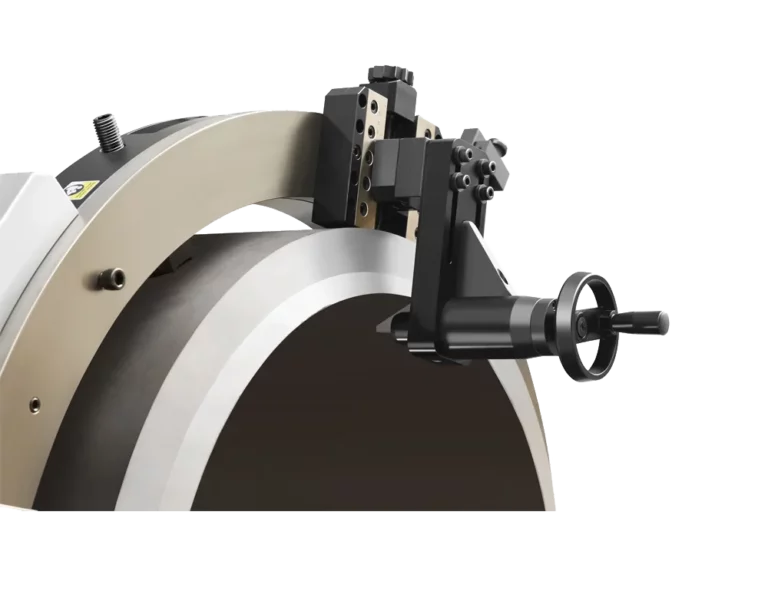

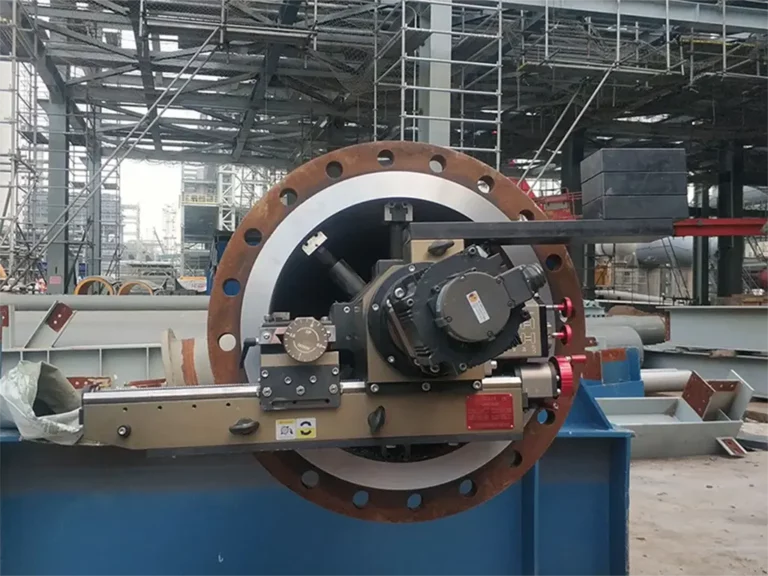

Maximizing Efficiency with the MFF350 Manual Flange Facer: A Comprehensive Guide

Flange facing is an essential process in the maintenance and repair of pipes and other industrial equipment. The MFF350 manual flange facer offers a convenient, efficient and cost-effective solution for flange facing tasks. With its hand-powered operation and a clamping range from 1.07″ to 10.63″, the MFF350 is designed to meet a wide range of on-site maintenance and repair needs.